Aplikasi

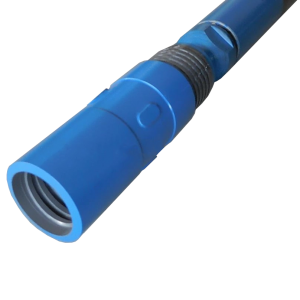

Rol cone bit minangka alat sing paling akeh digunakake ing pengeboran petroleum lan pengeboran geologi.Tricone bit nduweni fungsi impact, crushing lan shearing rock ing tatanan, supaya bisa adaptasi kanggo tatanan alus, medium lan hard.Cone bit bisa dipérang dadi penggilingan (steel untu) cone bit lan TCI cone bit miturut jinis untu.

Karakteristik

Miturut materi nglereni, bisa dipérang dadi waos baja (gilingan waos) lan tungsten carbide insert (TCI) waos rol conthong.

TCI Tricone bit pengeboran kanggo medium kanggo tatanan rock hard.

Bit tricone TCI formasi medium nampilake sisipan chisel tungsten carbide agresif ing larik tumit lan larik njero.

Desain iki menehi tingkat pengeboran cepet lan nambah kekiatan struktur nglereni ing medium kanggo tatanan hard medium.O-ring karet HSN nyedhiyakake sealing sing cukup kanggo daya tahan bantalan.

The hard formasi TCI tricone bit bisa digunakake kanggo pengeboran hard lan tatanan abrasive.Nyandhang sisipan tungsten karbida tahan digunakake ing baris njaba kanggo nyegah mundhut bit gauge.Jumlah maksimum sisipan shaped hemispherical digunakake ing kabeh larik kanggo nyedhiyani kekiatan cutter lan umur dawa.

Struktur bit Tricone

Pandhuan Tricone Bit Choice

| IADC | WOB (KN/mm) | RPM(r/min) | FORMASI sing bisa ditrapake |

| 114/116/117 | 0,3 nganti 0,75 | 180~60 | Formasi sing alus banget kanthi kekuatan tekan sing kurang lan kemampuan pengeboran sing dhuwur, kayata lempung, mudstone, kapur, lsp. |

| 124/126/127 | 0.3~0.85 | 180~60 | Formasi alus kanthi kekuatan tekan sing kurang lan kemampuan pengeboran sing dhuwur, kayata mudstone, gypsum, uyah, watu gamping alus, lsp. |

| 134/135/136/137 | 0.3~0.95 | 150~60 | Formasi alus nganti medium kanthi kekuatan tekan sing kurang lan kemampuan pengeboran sing dhuwur, kayata shale alus medium, gipsum hard, watu gamping alus medium, watu pasir alus medium, tatanan alus karo interbed harder, etc. |

| 214/215/216/217 | 0.35~0.95 | 150~60 | Formasi medium kanthi kekuatan kompres dhuwur, kayata serpih alus medium, gipsum keras, watu gamping alus medium, watu pasir alus medium, formasi alus kanthi interbed sing luwih angel, lsp. |

| 227 | 0.35~0.95 | 150~50 | Formasi medium hard kanthi kekuatan tekan dhuwur, kayata abrasive shale, limestone, sandstone, dolomit, hard gypsum, marmer, etc |

| Cathetan: Watesan ndhuwur WOB lan RPM ing tabel ndhuwur ora bisa digunakake bebarengan. | |||

Pandhuan saka tricone Bits ChoiceTipe Gigi Tricone Bits

Ukuran Bit

| Ukuran Bit | API REG PIN | Torsi | Bobot | |

| inch | mm | inch | KN.M | Kgs |

| 3 3/8 | 85.7 | 2 3/8 | 4.1-4.7 | 4.0-6.0 |

| 3 1/2 | 88.9 | 4.2-6.2 | ||

| 3 7/8 | 98.4 | 4.8-6.8 | ||

| 4 1/4 | 108 | 5.0-7.5 | ||

| 4 1/2 | 114.3 | 5.4-8.0 | ||

| 4 5/8 | 117.5 | 2 7/8 | 6.1-7.5 | 7.5-8.0 |

| 4 3/4 | 120.7 | 7.5-8.0 | ||

| 5 1/8 | 130.2 | 3 1/2 | 9.5-12.2 | 10.3-11.5 |

| 5 1/4 | 133.4 | 10.7-12.0 | ||

| 5 5/8 | 142.9 | 12.6-13.5 | ||

| 5 7/8 | 149.2 | 13.2-13.5 | ||

| 6 | 152.4 | 13.6-14.5 | ||

| 6 1/8 | 155.6 | 14.0-15.0 | ||

| 6 1/4 | 158.8 | 14.4-18.0 | ||

| 6 1/2 | 165.1 | 14.5-20.0 | ||

| 6 3/4 | 171.5 | 20.0-22.0 | ||

| 7 1/2 | 190.5 | 4 1/2 | 16.3-21.7 | 28.0-32.0 |

| 7 5/8 | 193.7 | 32.3-34.0 | ||

| 7 7/8 | 200 | 33.2-35.0 | ||

| 8 3/8 | 212.7 | 38.5-41.5 | ||

| 8 1/2 | 215.9 | 39.0-42.0 | ||

| 8 5/8 | 219.1 | 40.5-42.5 | ||

| 8 3/4 | 222.3 | 40.8-43.0 | ||

| 9 1/2 | 241.3 | 6 5/8 | 38-43.4 | 61.5-64.0 |

| 9 5/8 | 244.5 | 61.8-65.0 | ||

| 9 7/8 | 250.8 | 62.0-67.0 | ||

| 10 | 254 | 68.0-75.0 | ||

| 10 1/2 | 266.7 | 72.0-80.0 | ||

| 10 5/8 | 269.9 | 72.0-80.0 | ||

| 11 1/2 | 292.1 | 79.0-90.0 | ||

| 11 5/8 | 295.3 | 79.0-90.0 | ||

| 12 1/4 | 311.2 | 95.0-102. | ||

| 12 3/8 | 314.3 | 95.0-102.2 | ||

| 12 1/2 | 317.5 | 96.0-103.0 | ||

| 13 1/2 | 342.9 | 105.0-134.0 | ||

| 13 5/8 | 346.1 | 108.0-137.0 | ||

| 14 3/4 | 374.7 | 7 5/8 | 46.1-54.2 | 140.0-160.0 |

| 15 | 381 | 145.0-165.0 | ||

| 15 1/2 | 393.7 | 160.0-180.0 | ||

| 16 | 406.4 | 200.0-220.0 | ||

| 17 1/2 | 444.5 | 260.0-280.0 | ||

| 26 | 660.4 | 725.0-780.0 | ||

Proses Produksi

| Jumlah Pesenan Minimal | N/A |

| Rega | |

| Rincian Kemasan | Paket Pengiriman Standar Ekspor |

| Wektu Pangiriman | 7 dina |

| Syarat-syarat pembayaran | T/T |

| Kapabilitas Pasokan | Adhedhasar Pesenan Detil |